KSL Metalworking Services

Application Equipment

In-plant efficiencies are readily achieved. Ask your KSL representative for assistance in the dilution, delivery and re-use of your products.

KSL designs custom solutions for your delivery requirements. Our systems include:

- Delivery equipment

- Central systems

- Vacuum filters

- Magnetic separators

- PLC controlled concentrate dilution systems

- Dema controlled concentrate dilution systems

- Plant installations

- Piping installations

- Automatic Dilution Systems

Reuse and Recycling

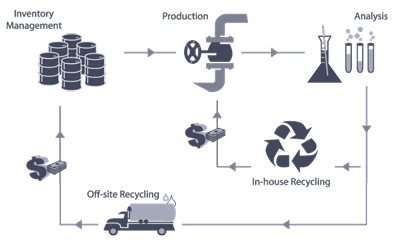

Total Process Management (TPM), part of KSL's Life Cycle Management program, manages all your industrial fluids, including procurement, warehousing, recycling, disposal, and technical support. We focus on generating a new source of cost savings for our customers through process control, extended product life, usage reduction and waste minimization.

Inventory Management

Our trained engineering staff will assist you in the specification and selection of the lubricants, coolants, and cleaners for your process environment. After specification and selection we'll manage procurement and inventory control to meet your production needs.

Analysis

During and after use, all fluids go through a sampling and analysis process. We'll monitor fluid integrity to ensure optimal performance based on predefined specifications.

Recovery

In some cases fluids can be purified on-site for reuse and/or repurposing. This may involve flashing off water and the reintroduction of key ingredients to bring the product back to virgin state. In other cases, the process is more complex and involves removal to a KSL managed facility for purification and disposal of residual waste by registered government agencies. KSL can extend the life of your industrial lubricants, coolants, and cleaners indefinitely, with total costs 25% to 50% lower than traditional methods and with the added benefit of reduced environmental impact.